Mastering monitoring tools for improved Thrips control.

Photo: Charles Njuki inspecting a Sticktech sticky card.

By Festus Kilee, John Ogechah and Cory Smit

As more growers around the world face Thrips (Order: Thysanoptera) and the crop challenges they bring, information and understanding have never been more important. Unnoticed Thrips challenges pose a significant threat to growers as their populations can quickly balloon, impacting on crop production, quality and overall cost. In particular, when crops are destined for overseas markets which are typically sensitive to quality and have strict phytosanitary restrictions in place, ignoring this threat may result in significant financial losses when the crop fails to make it to market. Inversely, with Thrips monitoring data available, growers can run timely interventions and target hot-spots. Early detection then translates into reduced spray volumes and reduced crop losses.

Fortunately, there are well-established methods of tracking and monitoring Thrips populations on crops. By regularly gathering Thrips data using sticky traps, pheromone lures and manual observation techniques, growers can get a head start and inform their control decisions, mitigate crop losses and save money.

Methods of early detection

Global crop protection research efforts have resulted in a number of monitoring tools and techniques being developed for use in a farm environment. In this article, we will cover scouting, traps and pheromone lures for Thrips (however, these techniques can be applied to a variety of other flying crop pests.)

Scouting

Scouting uses visual inspections of the plants to note Thrips presence and pressure. A simple technique involves counting larvae by gently tapping a sample of the crop onto an A4-sized sheet of white paper, any Thrips which drop to the paper are then counted using a magnifying lens or loupe and recorded.

Sticky traps

Different insect pests are attracted to different colours (wavelengths of light), with yellow and blue so far proving most attractive to crop pests. For example, Western flower thrips (Frankliniella occidentalis) which are most common and difficult to control, particularly favour blue traps over yellow ones.

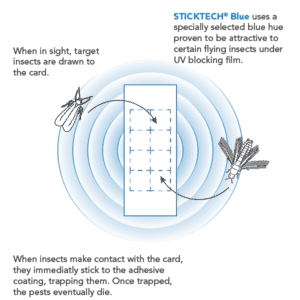

Fig. 1. Sticktech Blue mode of action.

The colour-tuned material on these traps attracts the pests to an adhesive covered surface, which they then stick to, becoming trapped. Researchers or growers, then collect the data from the traps by counting and identifying the Thrips and other insects caught. This data, when plotted over time, reveals the pest trends for the area in question.

Dudutech has a range of tools for early detection of flying stages:

- Sticktech – uses blue or yellow sticky cards which are placed between 10 – 15 cm above the plant canopy.

- Optiroll – uses blue or yellow sticky rolls which are hung between poles and positioned 10 – 15 cm above the plant canopy.

Pheromones

These are synthetic chemical signals which mimic natural insect pheromones to attract the target to a trap. Since these are based on nature, these pheromone lures are species-specific. However, there are a wide variety of pheromone lures available for a number of important crop pests.

What other benefits?

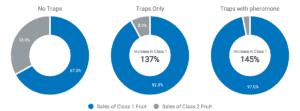

Beyond the scope of pure observation, these sticky traps are also a valuable part of successful IPM practices. When researchers (Kirk and Sampson, 2013) looked at the potential economic returns gained from using traps and pheromones as part of a crop protection strategy for strawberries, they revealed a quality effect on the overall yield. The charts below illustrate their findings:

Chart 1. Quality effect of sticky traps in strawberries (Kirk and Sampson, 2013).

In summary, Kirk and Sampson (2013) found that trapping significantly increased the proportion of Class 1 fruit, and pheromones further improved their efficacy. These measures would be particularly suited to growers who wish to optimise their yield quality and those whose crops undergo strict quality checks before entering the market.

When used together, these tools can provide a thorough picture of the current and future trends in Thrips challenges on a farm. Having these measures in place early could provide the vital data farmers need to make informed and well-timed crop protection decisions, reducing cost and improving crop quality.

Want to know more?

Contact us on info@dudutech.com

Chart 1 developed from the following research paper:

Sampson, Clare & Kirk, William. (2013). Can Mass Trapping Reduce Thrips Damage and Is It Economically Viable? Management of the Western Flower Thrips in Strawberry. PloS one. 8. e80787. 10.1371/journal.pone.0080787.